I-performer magnetic esisigxina yindlela ekhawulezayo, ekhuselekileyo kunye nelula yokunyusa iipleyiti zetsimbi, iibhloko zentsimbi kunye nezixhobo zentsimbi ze-cylindrical, ezifana neengxenye zomatshini, i-punch molds kunye neentlobo ezahlukeneyo zezinto zentsimbi.

Yenziwe ngamacandelo amabini, i-sucker esisigxina kunye nesixhobo sokukhupha. I-sucker esisigxina yenziwe ngemagnethi esisigxina ye-Neodymium kunye nepleyiti eqhuba umazibuthe. Imigca yamandla omagnetic eyenziwe yimagnethi ye-Neodymium idlula kwipleyiti yemagnethi-conductive, izinto ezitsalayo kwaye zenze isekethe evaliweyo ukufezekisa injongo yokuphakamisa izinto zentsimbi. Isixhobo sokukhupha sibhekisa ikakhulu kwisiphatho. Isetyenziswa ngokubanzi kumashishini oomatshini, ukuveliswa komngundo, iindawo zokugcina iimpahla kunye namasebe okuthutha ukuthutha iipleyiti zetsimbi, iingots zentsimbi kunye nezinye izinto ezisebenza ngombane.

1.Ubungakanani obuncinci kunye nobunzima obulula

2.Ukukhawuleza kwaye kulula ukusebenza kunye ne-ON / OFF inkqubo / isibambo

Uyilo lwegroove olumilise okwe-3.V emazantsi luvumela umazibuthe ofanayo wokuphakamisa olungele zombini izinto ezisicaba nezingqukuva.

I-4.Force inikwe amandla yibakala elomeleleyo lemagnethi yomhlaba enqabileyo yeNeodymium

5.I-chamfering enkulu ejikeleze emazantsi ikhusela ngokufanelekileyo ukuthe tyaba komphezulu ongezantsi kunye nokuvumela isiphakamisi somagnetic ukuba sisebenzise ngokupheleleyo amandla ayo omagnetic.

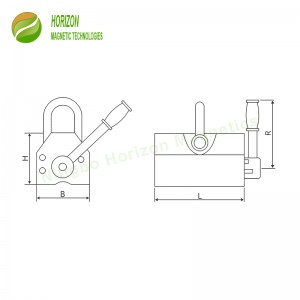

| Inombolo yendawo | Ulinganiso lwamandla okuPhakamisa | Amandla aphezulu okutsalwa | L | B | H | R | Ukusinda okushiyekile | Ubushushu obuphezulu bokusebenza | |

| kg | kg | mm | mm | mm | mm | kg | °C | °F | |

| PML-100 | 100 | 250 | 92 | 65 | 69 | 155 | 2.5 | 80 | 176 |

| PML-200 | 200 | 550 | 130 | 65 | 69 | 155 | 3.5 | 80 | 176 |

| PML-300 | 300 | 1000 | 165 | 95 | 95 | 200 | 10.0 | 80 | 176 |

| PML-600 | 600 | 1500 | 210 | 115 | 116 | 230 | 19.0 | 80 | 176 |

| PML-1000 | 1000 | 2500 | 260 | 135 | 140 | 255 | 35.0 | 80 | 176 |

| PML-1500 | 1500 | 3600 | 340 | 135 | 140 | 255 | 45.0 | 80 | 176 |

| PML-2000 | 2000 | 4500 | 356 | 160 | 168 | 320 | 65.0 | 80 | 176 |

| PML-3000 | 3000 | 6300 | 444 | 160 | 166 | 380 | 85.0 | 80 | 176 |

| PML-4000 | 4000 | 8200 | 520 | 175 | 175 | 550 | 150.0 | 80 | 176 |

| PML-5000 | 5000 | 11000 | 620 | 220 | 220 | 600 | 210.0 | 80 | 176 |

1. Ngaphambi kokuba uphakamise, coca umphezulu womsebenzi oza kuphakanyiswa. Umgca osembindini weemagnethi zokuphakamisa isigxina kufuneka uhambelane nombindi womxhuzulane wesixhobo sokusebenza.

2. Kwinkqubo yokuphakamisa, ukulayisha ngaphezulu, abantu abaphantsi kwe-workpiece okanye i-vibration enzima inqatshelwe ngokungqongqo. Ubushushu bomsebenzi kunye nobushushu be-ambient kufuneka bube ngaphantsi kwe-80C degrees.

3. Xa uphakamisa i-workpiece ye-cylindrical, i-V-groove kunye ne-workpiece kufuneka igcinwe idibene nemigca emibini echanekileyo. Umthamo wayo wokuphakamisa yi-30% - 50% kuphela yamandla okunyusa alinganisiweyo.