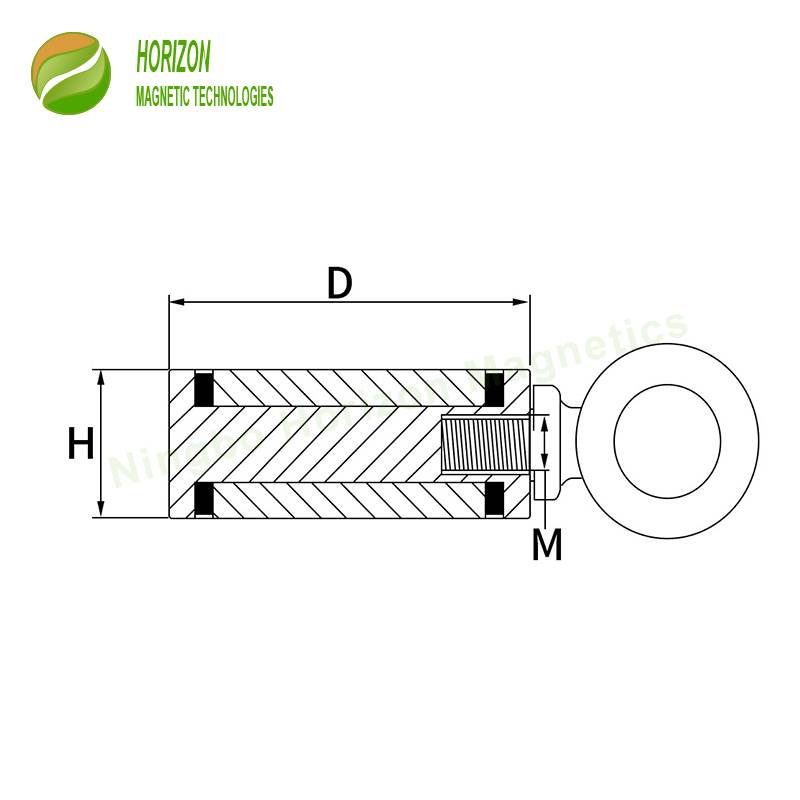

1. Interchangeable steel stainless eyebolt: Olu luyilo luvumela abasebenzisi ukuba basebenzise amagwegwe abo akhethekileyo endaweni yokuhlangabezana nesicelo sabo esikhethekileyo.

2. Ukuqina okuphezulu phakathi kwe-eyebolt kunye nemagnethi yokuloba: Iringi egciniweyo inciphisa umngcipheko we-eyebolt exhasa kunye nokulahlekelwa yimagnethi yokuloba.

3. Amacala atsala kabini: Olu luyilo luphinda kabini indawo ngamandla omagnetic, oluya kwenza imagnethi yokuloba emacala omabini alinganayo yandise amathuba okuzingela ubutyebi ngempumelelo.

1. I-R&D kunye nokulinganisa: Ngokwemfuno entsonkothileyo yabathengi, kufuneka singene kwi-R&D kunye nenkqubo yokulinganisa, ukufumana iimfuno ezineenkcukacha zemagnethi kubandakanya imathiriyeli yemagnethi, imilo, ubungakanani, isambatho kunye nebakala, izinto zentsimbi kunye nobukhulu obuhambelanayo, indlela yokudibanisa amacandelo, njl. Kwaye ke isampuli iyimfuneko ukugqibezela uyilo.

2. Ukwenziwa kwemvelisoImagnethi yeNeodymium: Ngexesha lenkqubo yebhloko yemagnethi, ukubunjwa kwemagnethi kunye neteknoloji yokuvelisa kufuneka ilawulwe ngokungqongqo, ephantse igqibe ukubamba amandla kunye nomgangatho wemagnethi yokuloba emacala amabini. Ngamanye amaxesha, ibakala lemagnethi kufuneka libe phezulu kunebanga elisezantsi njenge-N35, ke ukufikelela kumandla aphezulu afunekayo kunye nobukhulu obuncinci.

3. Ukukhetha izinto zetsimbi kunye ne-machining steel case: Izinto eziphathekayo zentsimbi zikwabalulekile ukuphembelela amandla okutsala, kuba intsimbi yentsimbi kufuneka incede amandla ombane omhlaba onqabileyo we-NdFeB umazibuthe ogxininiswe kwiziko kuphela. Ngaphezu koko, intsimbi yentsimbi inokukhusela i-NdFeB umazibuthe osisigxina ekuqhekekeni nasekuqhekekeni. I-case material is low carbon steel.

4. Ukuzalisa i-epoxy emnyama: Umsantsa phakathi kwemagnethi ye-NdFeB kunye necala lentsimbi lizaliswe nge-epoxy emnyama, enokulungisa i-Neodymium umazibuthe kwi-case yentsimbi ngokuqinileyo, kwaye emva koko ikhusele i-disc Neodymium umazibuthe ekuweni kwaye yandise ixesha layo lenkonzo.

1. Umgangatho ophezulu: Imagnethi ye-NdFeB, eyona nxalenye ibalulekileyo iveliswa yifektri yethu, eyenza ukuba senze umgangatho wemagnethi phantsi kolawulo.

2. Iindleko ezisebenzayo: Imveliso yangaphakathi isenza ukuba siqinisekise ukuba imagnethi yethu yokuloba ikumgangatho ofanayo kodwa ngexabiso eliphantsi xa ithelekiswa nezo sikhuphisana nazo.

3. Unikezelo olukhawulezayo: Iimveliso ezininzi ezigqityiweyo kancinci kwisitokhwe kunye nesakhono sokuyila ngaphakathi kuvumela ukuhanjiswa kwangethuba kwemagnethi yokuloba.

4. Iinketho ezininzi: Iinketho ezininzi ezisemgangathweni ziyafumaneka. Ngaphezu koko, imveliso yethu yangaphakathi kunye nemveliso yenza ukuba ukhetho olulungelelanisiweyo lweenkqubo zemagnethi kubathengi ngokulula. Singakwazi ukuhlangabezana nokuthenga okulula okukodwa.

| Inombolo yendawo | D | H | M | Ngenyanzelo | Ukusinda okushiyekile | Ubushushu obuphezulu bokusebenza | ||

| mm | mm | mm | kg | lbs | g | °C | °F | |

| HM-S1-48 | 48 | 18 | 8 | 80 | 176 | 275 | 80 | 176 |

| HM-S1-60 | 60 | 22 | 8 | 120 | 264 | 500 | 80 | 176 |

| HM-S1-67 | 67 | 25 | 10 | 150 | 330 | 730 | 80 | 176 |

| HM-S1-75 | 75 | 25 | 10 | 200 | 440 | 900 | 80 | 176 |

| HM-S1-94 | 94 | 28 | 10 | 300 | 660 | 1540 | 80 | 176 |

| HM-S1-116 | 116 | 32 | 12 | 400 | 880 | 2650 | 80 | 176 |

| HM-S1-136 | 136 | 34 | 12 | 600 | 1320 | 3850 | 80 | 176 |