Yenziwe ngerabha ngaphandle, ngaphakathi kwemagnethi yeNeodymium, istud sentsimbi kunye nepleyiti yentsimbi. Ngokungafaniyo neumazibuthe wembiza jikelelengemagnethi enye kuphela enkulu enamandla ebiyelwe ngaphakathi kweqokobhe lembiza, ngokubanzi imagnethi eqatywe irabha egqunywe ngerabha yangaphandle iveliswa ngeendlela ezincinci ezahlukeneyo.Imagnethi yediski yeNeodymiumifakwe kwipleyiti enye yentsimbi. Imagnethi ye-Neodymium ayibekwanga ngokungenamkhethe, kodwa ibekwe ngokwesekethe eyilwe ngononophelo ukuze yenze yonke imbiza yerabha egqunywe nguzibuthe ibe namandla okubamba. Isigqubuthelo serabha esikhuselayo sigubungela wonke umphezulu weemagnethi zeNeodymium kunye nepleyiti yentsimbi, ngaphandle kwestud sangaphandle esishiyekileyo.

1. Inokuba yeyona ndlela ilungileyo yokuzalisekisa injongo yokubamba kwindawo ethambileyo ngaphandle komonakalo ngenxa yokuba irabha ethambileyo yokugquma inokuthintela imikrwelo yomhlaba kwaye inikeze ukuchasana kwe-slip ephezulu. umz. ukubamba izibane zeLed kwiilori ezingaphandle kwendlela okanye iimoto.

2. Kwezinye indawo ezimanzi okanye ezinye iikhemikhali umhlwa, ukutyabeka irabha inokukhusela umazibuthe Neodymium ekuvezeni kwindawo umhlwa ngqo ukwandisa ixesha layo lenkonzo.

3. Steel stud lwangaphandle kwenza irabha camera Neodymium umazibuthe lula ukukhwela izinto imingxunya ngemisonto.

1. Imathiriyeli yemagnethi yeNeodymium yokwenyani kunye neempawu eziqhelekileyo zemagnethi, ubungakanani bemagnethi kunye namandla UNGAZE ube ncinane kunemfuneko.

2. Ubungakanani obuqhelekileyo kwisitokhwe kwaye buyafumaneka ukuhanjiswa kwangoko

3. Iindidi ezininzi zemagnethi kunye neenkqubo zemagnethi zeNeodymium eziveliswe ngaphakathi endlwini ukuhlangabezana nomthombo wokumisa omnye weemveliso zemagnethi.

4. Izisombululo ezenziwe ngokwezifiso ziyafumaneka xa ziceliwe

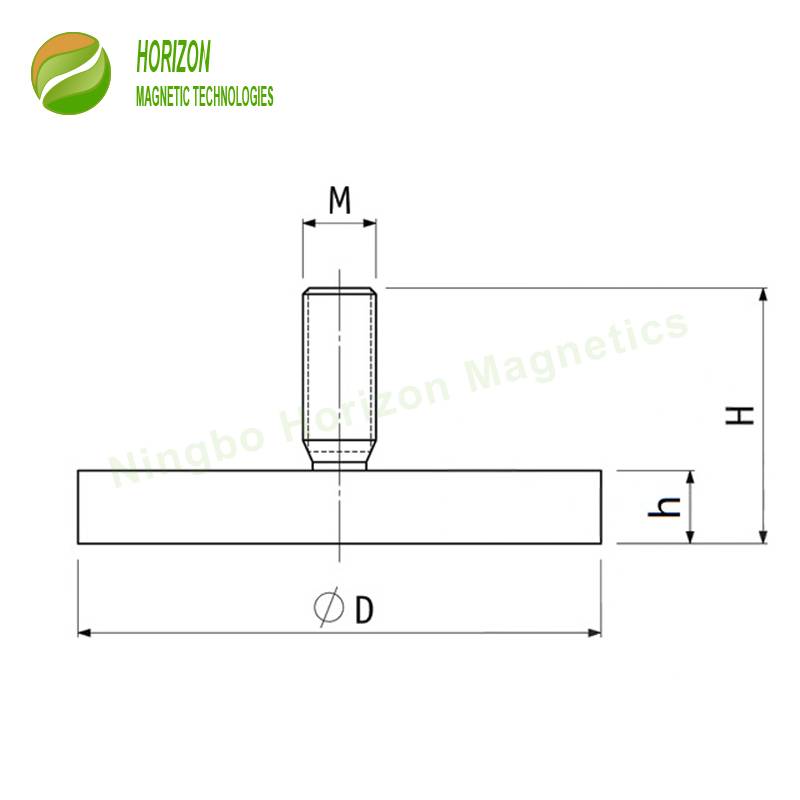

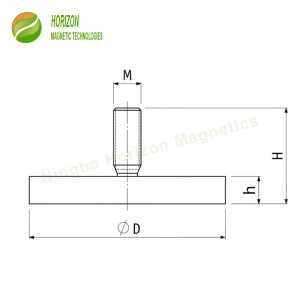

| Inombolo yendawo | D | M | H | h | Ngenyanzelo | Ukusinda okushiyekile | Ubushushu obuphezulu bokusebenza | ||

| mm | mm | mm | mm | kg | lbs | g | °C | °F | |

| HM-H22 | 22 | 4 | 12.5 | 6 | 5 | 11 | 15 | 80 | 176 |

| HM-H34 | 34 | 4 | 12.5 | 6 | 7.5 | 16.5 | 26 | 80 | 176 |

| HM-H43 | 43 | 6 | 21 | 6 | 8.5 | 18.5 | 36 | 80 | 176 |

| HM-H66 | 66 | 8 | 23.5 | 8.5 | 18.5 | 40 | 107 | 80 | 176 |

| HM-H88 | 88 | 8 | 23.5 | 8.5 | 43 | 95 | 193 | 80 | 176 |