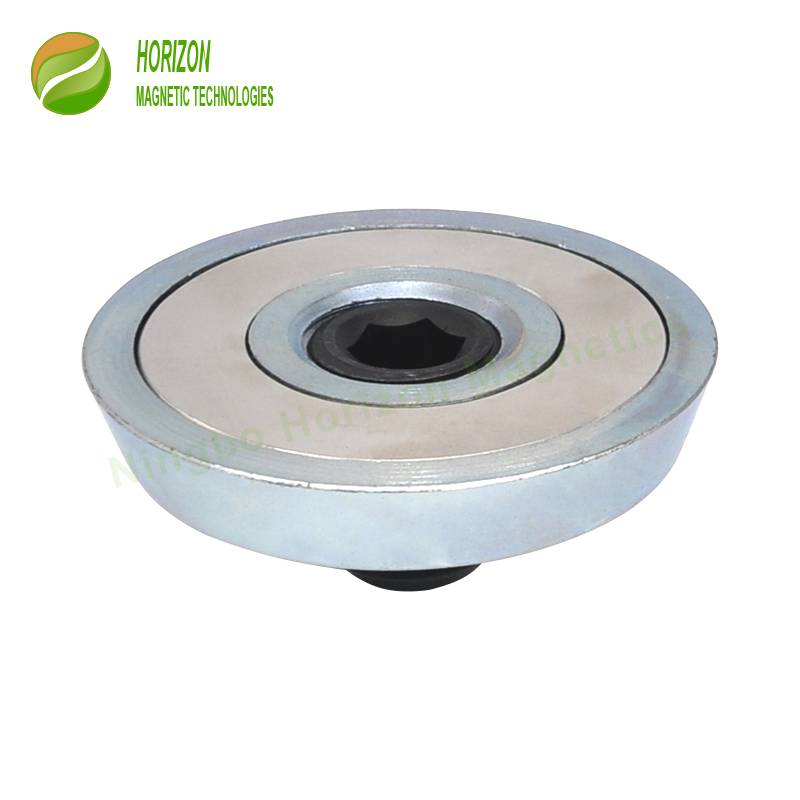

Kuyafana nje neImagnethi yembiza yeNeodymium, imagnethi yokufaka iquka i-NdFeB umazibuthe, i-casing yentsimbi kunye nentonga enentambo. Isingxobo sentsimbi sikhusela umazibuthe we-Neodymium kumonakalo wangaphandle kwaye sigxininise kumandla kazibuthe ovalelweyo.Imagnethi yeringi yeNeodymiumkumphezulu oqhagamshelwe kuphela ukuvelisa amandla aphezulu kakhulu kunemagnethi yeNeodymium eyahlukileyo. Nangona kunjalo inamanqaku athile ahlukeneyo ukusuka kwimagnethi yembiza ukuze ihlangabezane neemfuno zesicelo kwikhonkrithi yangaphambili. Ubume be-casing yensimbi i-tapered kwaye intonga ene-threaded iyatshintsheka ukwenzela ukuba i-magnet yokufaka ikulungele ukukhupha kwikhonkrithi eqinile ngokusebenzisa i-socket wrench.

1. Izinto eziphathekayo: Imagnethi ye-Neodymium kunye nokusebenza okuphezulu kunye nebakala + I-Casing yentsimbi kunye nentonga

2. Ukwaleka: Imagnethi iqatywe ngeNiCuNi okanye iZinc + intsimbi yentsimbi eqatywe ngeZinc okanye iCopper.

3. Ubungakanani kunye nokunyanzeliswa: Ngokubhekiselele kwiDatha yoBugcisa

4. Iphakheji: Ipakishwe kwiibhokisi zamazinki. Iikhathoni ezipakishwe kwipalethi yomthi okanye ikesi yobuninzi

1. Amandla emagnethi kunye noyilo olulodwa kunye nesakhiwo senza ukukhanya kwaye kube lula ukusebenza.

2. Iyasebenziseka kwakhona kwaye ihlala ixesha elide ukugcina iindleko ekwabelwana ngazo kwixesha elide.

3. Ukukhawuleza ukubeka kunye nokuphucula ukusebenza kakuhle kunye neendleko.

4. Inokuphucula umgangatho wezinto eziphathekayo ze-precast.

5. Amandla emagnethi aphakamileyo ngokwaneleyo ukubeka kunye nokuqinisa amacandelo afakwe ngokuchanekileyo ngexesha lokuphosa ikhonkrithi okanye inkqubo yokungcangcazela ukwenzela ukuba usebenze ngokukhuselekileyo.

1. Ulwazi olungenakuhlulwa kwimagnethi yeNeodymium, elona candelo libalulekileyo lokuqinisekisa umgangatho wemagnethi.

2. Ulwazi lwemagnethi kunye noyilo lwangaphakathi lunceda abathengi baqonde iimveliso zabathengi ukusuka kwingqikelelo ukuya kwiimveliso zokugqibela zikamagnetic ngokulula.

3. Izitayile ezininzi kunye neesayizi ezikhoyo ukugcina iindleko zezixhobo kunye nexabiso lemveliso kubathengi

4. Ubungakanani obuqhelekileyo kwisitokhwe kwaye buyafumaneka ukuhanjiswa kwangoko

5. Gqibezela unikezelo lweemagnethi zekhonkrithi eziye zangaphambili kuqukaimagnethi yokuvala, ii-chamfers zemagneti kunye neemveliso zemagnethi ezenziwe ngokwesiko ukuhlangabezana nokuthengwa kwabathengi

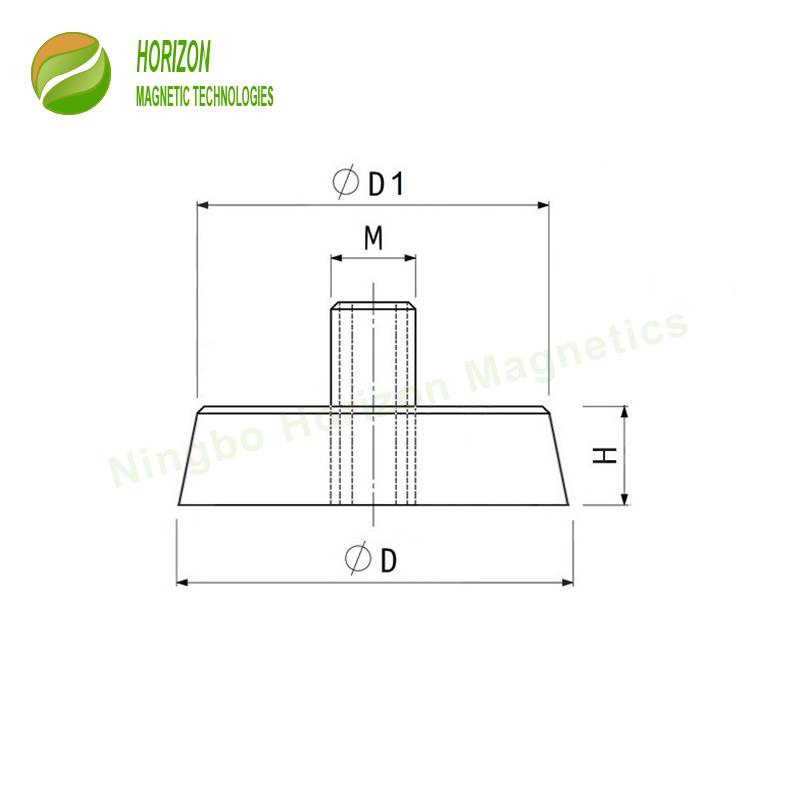

| Inombolo yendawo | D | D1 | H | M | Ubushushu obuphezulu bokusebenza | |

| mm | mm | mm | mm | °C | °F | |

| I-HM-IN45-M8 | 45 | 40 | 8 | 8 | 80 | 176 |

| I-HM-IN45-M10 | 45 | 40 | 8 | 10 | 80 | 176 |

| I-HM-IN54-M12 | 54 | 48 | 10 | 12 | 80 | 176 |

| I-HM-IN54-M16 | 54 | 48 | 10 | 16 | 80 | 176 |

| HM-IN60-M20 | 60 | 54 | 10 | 20 | 80 | 176 |

| I-HM-IN77-M24 | 77 | 73 | 12 | 24 | 80 | 176 |

1. Kuphephe ukugquma umphezulu wemagnethi yeNeodymium evalelweyo ukuze ugcine amandla kazibuthe.

2. Sebenzisa okanye gcina umazibuthe ongaphantsi kwama-80℃. Ubushushu obuphezulu bunokubangela ukuba umazibuthe unciphise okanye ulahlekelwe ngokupheleleyo ngamandla kazibuthe.

3. Kucetyiswa kakhulu ukuba iiglavu kufuneka zinxitywe ukukhusela izandla zabasebenzi ekuxinaniseni impembelelo. Nceda uyigcine kude nezixhobo zombane kunye neentsimbi ezingeyomfuneko ze-ferromagnetic. Isilumkiso esikhethekileyo kufuneka sithatyathwe ukuba umntu unxibe isincedisi-ntliziyo, kuba amandla emagnethi anamandla anokonakalisa i-electronics engaphakathi kwi-pacemakers.