Sixhomekeke kumandla obugcisa owomeleleyo kwaye sihlala sisenza ubuchwephesha obuntsonkothileyo ukuhlangabezana neemfuno zeFactory ngokuthe ngqo IBhokisi yeSisimbi eNgatyiwayo yeMagnetic Precast Precast Concrete Shuttering Magnetic Formwork Precast Magnet, Khumbula ukusizisa iinkcukacha zakho kunye neenkcukacha zakho, okanye uzive ungenandleko ngokwenene ukuqhagamshelana nathi nayiphi na imibuzo okanye imibuzo onokuba nayo.

Sixhomekeke kumandla obugcisa owomeleleyo kwaye sihlala sisenza ubuchwephesha obuphucukileyo ukuhlangabezana nemfunoI-Precast Concrete Magnet kunye ne-Concrete Magnets, Singalamkela kakhulu ithuba lokwenza ishishini nawe kwaye siyonwabele ukuncamathelisa iinkcukacha ezithe vetshe zentengiso yethu. Umgangatho ogqwesileyo, amaxabiso akhuphisanayo, unikezelo ngexesha kunye nenkonzo ethembekileyo inokuqinisekiswa.

1. Izinto eziphathekayo: Imagnethi ye-Neodymium enomgangatho ophezulu wokusebenza kunye nebakala + Intsimbi yekhabhoni ephantsi

2. Unyango lomphezulu: iZinc, iNi+Cu+Ni, okanye i-epoxy yeNeodymium umazibuthe + iZinc, ipeyinti okanye obunye ubuchwephesha obufunekayo kwimeko yentsimbi.

3. Ipakethi: ipakishwe kwibhokisi enamazimba emva koko iibhokisi zipakishwe kwipalethi yomthi okanye ikesi. Inye, zimbini, zintathu okanye ezinye iziqwenga ezisekelwe kubukhulu ngekhathoni nganye

4. Ilever yokuphakamisa: Ukuphakamisa intambo simahla xa ubungakanani beodolo yemagnethi yokuvala inkulu kwaye kulula ukuyithumela kunye.

1. Izityalo ze-precast kunye nenkqubo yokuvelisa isigxina ukuvelisa izinto zekhonkrithi zangaphambili, njengama-slabs omgangatho okanye iindonga eziphindwe kabini

2. Iifektri ze-Precast zivelisa ukuvuleka okuntsokothileyo okanye okuncinci, njengeengcango okanye iifestile ezifuna iimagnethi ezininzi zokuvala ukuqinisa iiformworks.

3.

4. Naziphi na iinkampani ngaphandle koshishino lwe-precast abacinga ukuba umazibuthe ovalayo unokuhlangabezana neemfuno zabo malunga nokubamba amandla aphezulu kunye nokusebenza ngokulula.

1. I-Versatile malunga nazo zonke izinto zefomworks, umzekelo umthi, intsimbi okanye i-aluminium

2. Umazibuthe ofanayo ukuhlangabezana neenjongo ezahlukeneyo kwi-formworks yokuqinisa

3. Ubukhulu obuninzi kunye namandla aqala kwi-450 Kg ukuya kwi-3100 Kg ukuhlangabezana neemfuno zakho ezahlukeneyo.

4. Ubungakanani obuqinileyo, ukukhanya kunye nokulula ukusebenza

5. Ukuma okulula kunye nokuchanekileyo

6. Kuphephe ukuwelda okanye ukubolitha kwitheyibhile yeformwork ke ngoko ugcina ukugqitywa komphezulu

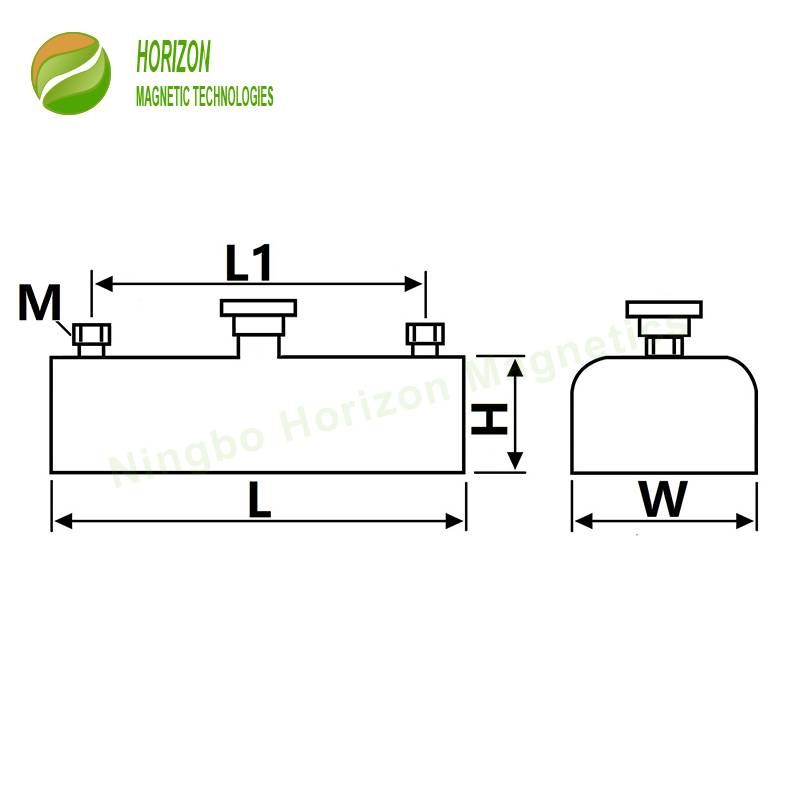

7. Imingxuma emibini enemisonto edibeneyo o ilungelelanisa ifomwork

Cinezela iqhosha elitshintshekayo phezu kwendawo yokugcina intsimbi ukuze uvule amandla emagnethi ukuqhoboshela iformwork kwitafile yentsimbi ngokuqinileyo. Sebenzisa i-lever yokuphakamisa ukutsalela phezulu iqhosha ukucima amandla omagnetic ukuhamba kunye nokubeka imagnethi yokuvala kwaye ulungelelanise iifomworks. Ngamanye amaxesha, sebenzisa imingxunya emibini enemisonto edityaniswe phezulu kwimagnethi yokuvala ukuncamathisela iiadaptha ezahlukeneyo, ukuze kuhlangatyezwane nemfuno yesicelo esingenamda.

1. Amandla okhuphiswano angenakuthelekiswa nanto kwelona candelo libalulekileyo, i-Neodymium umazibuthe, kuba i-Horizon Magnetics isuka kwaye isekwimveliso yemagnethi ye-Neodymium.

2. Ukuzithemba kumgangatho kunye nokwamkela imigaqo yentlawulo efana ne-100% T/T emva kokuba abathengi befumene iimagnethi zethu zokuvala

3. Gqibezela unikezelo lweemagnethi zekhonkrithi zangaphambili ezinje ngemagnethi, faka iimagnethi, kunye nesakhono somatshini wangaphakathi ukuvelisa iimveliso zemagneti ezenzelwe ukukhawulelana nokuthenga kwabathengi kanye.

| Inombolo yendawo | L | L 1 | H | M | W | Ngenyanzelo | Ubushushu obuphezulu bokusebenza | ||

| mm | mm | mm | mm | mm | kg | lbs | °C | °F | |

| HM-MF-0900 | 280 | 230 | 60 | 12 | 70 | 900 | 1985 | 80 | 176 |

| HM-MF-1600 | 270 | 218 | 60 | 16 | 120 | 1600 | 3525 | 80 | 176 |

| HM-MF-2100 | 320 | 270 | 60 | 16 | 120 | 2100 | 4630 | 80 | 176 |

| HM-MF-2500 | 320 | 270 | 60 | 16 | 120 | 2500 | 5510 | 80 | 176 |

| HM-MF-3100 | 320 | 270 | 60 | 16 | 160 | 3100 | 6835 | 80 | 176 |

1. Uluhlu lwangaphakathi lweemagnethi zeNeodymium kufuneka zigcinwe zicocekile. Kuphephe ukungena kwikhonkrithi ngaphakathi kwimagnethi evalayo ukuze kuqinisekiswe amandla alinganisiweyo ahleli kwaye iqhosha elitshintshekayo lisebenza ngokuguquguqukayo.

2. Emva kokusetyenziswa, kufuneka igcinwe icocekile kwaye ifakwe ioyile ukuze ikhuseleke ekudlekeni.

3. Ubushushu bokusebenza okanye ugcino kufuneka bube ngaphantsi kwe80℃. Ubushushu obuphezulu bunokubangela umazibuthe ovalayo unciphise okanye uphulukane ngokupheleleyo namandla kazibuthe.

4. Nangona phantse akukho mandla kazibuthe aviwayo ngaphandle kwentsimbi yesingxobo semagnethi evalayo, amandla emagnethi kwicala elisebenzayo anamandla kakhulu. Nceda uyigcine kude nezixhobo zombane kunye neentsimbi ezingeyomfuneko ze-ferromagnetic. Isilumkiso esikhethekileyo kufuneka sithatyathwe ukuba umntu unxibe isincedisi-ntliziyo, kuba amandla emagnethi anamandla anokonakalisa i-electronics ngaphakathi kwe-pacemakers. I-Formwork Precast Magnet, Khumbula ukusizisa iinkcukacha zakho kunye neenkcukacha zakho, okanye uzive ungenandleko ngokwenene ukuqhagamshelana nathi nayiphi na imibuzo okanye imibuzo onokuba nayo.

Factory ngqoI-Precast Concrete Magnet kunye ne-Concrete Magnets, Singalamkela kakhulu ithuba lokwenza ishishini nawe kwaye siyonwabele ukuncamathelisa iinkcukacha ezithe vetshe zentengiso yethu. Umgangatho ogqwesileyo, amaxabiso akhuphisanayo, unikezelo ngexesha kunye nenkonzo ethembekileyo inokuqinisekiswa.